New Year, New Packaging Company

It's 2026, the set up of ACDSleeve took much much longer than anticipated, but I'm on the home stretch to be ready to take on orders. I'm settled in the office, the CNC cardboard cutter has been delivered / installed and I now have a printer in house, which should make orders and custom work much more streamlined. The space is almost finished, just a couple of custom benches/board storage to come in February. It's crazy that this is only day 30 in the new space.

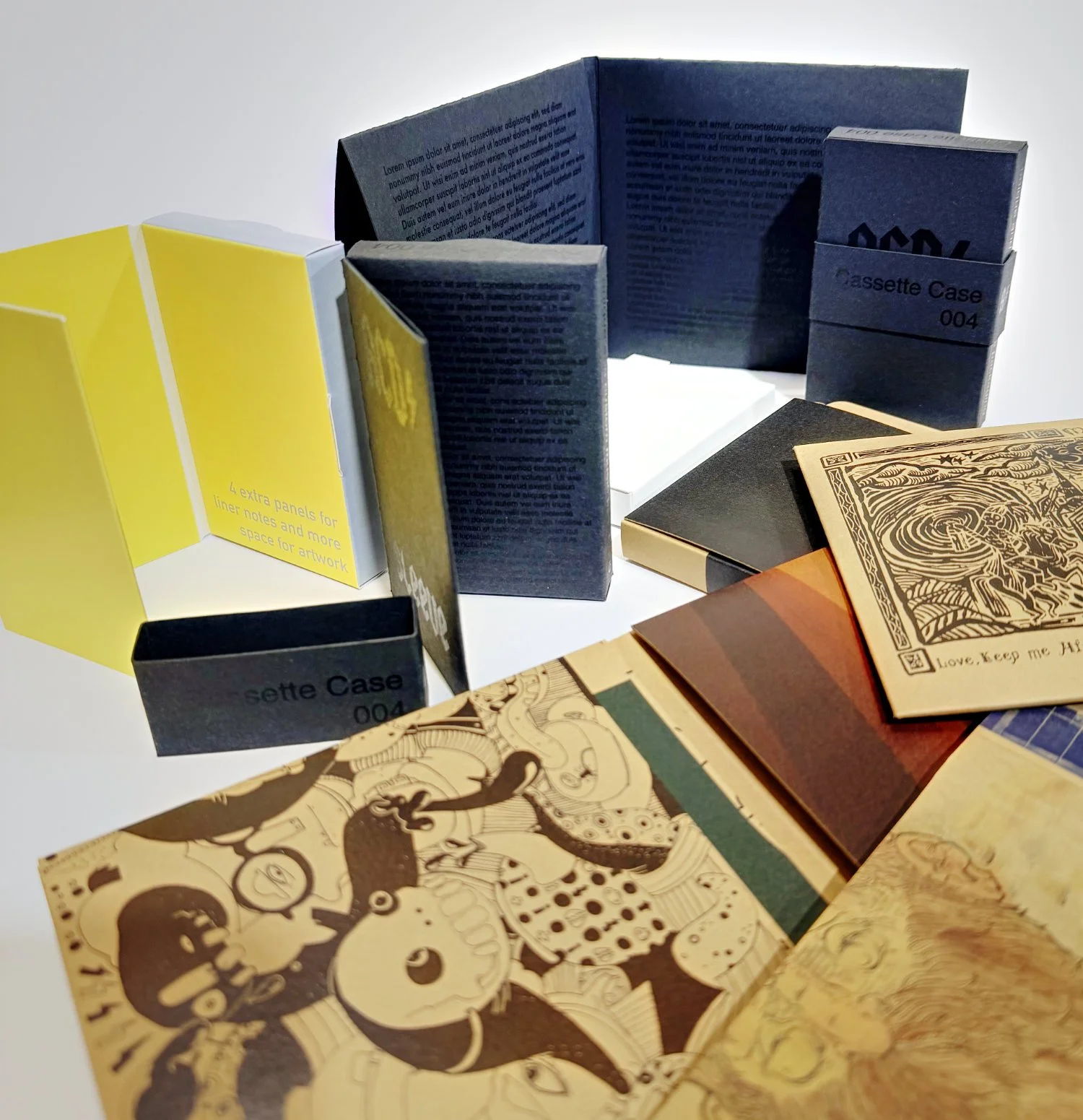

I'm currently going through every old design, refining it, getting it ready for production, creating artwork guides, figuring out pricing and the general workflow of everything. New designs are already being developed but I need to concentrate on getting ideas I know work out first.

The starting point of ACDSleeve v2 is a base of products designed by me, printed in house on brown board, cut/creased in house, and assembled by myself. Starting out with full colour print on brown 350GSM/470micron board will be the only option available, experiments with black print on black board are going well but need tweaks in production. After trying to find a white board to print in house after many samples from multiple suppliers I've had to admit defeat and revert to outsourcing this, turning back to one of the first printers I used when I first started. Print on white board will eventually be done on their HP Indigo press and then matt laminated. I'll still be handling cut/crease/assembly to keep quality levels where I want them to be. I would have loved to remove the plastic from the process but the cracking of print on creases on white uncoated board doesn't hit the quality I'm aiming for. Lamination has some benefits to introduce new additional options down the line though.

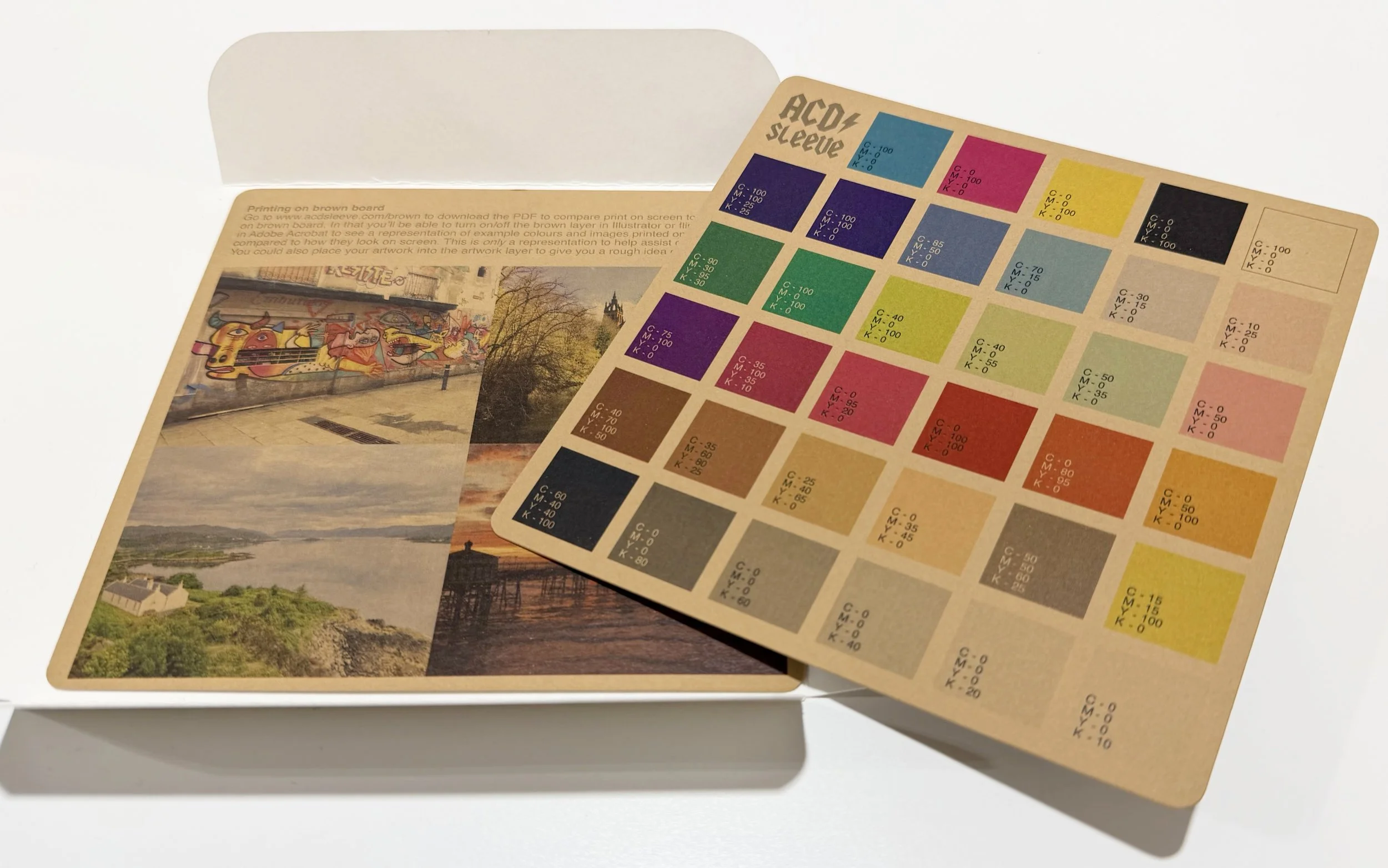

I'm aware that only offering print on brown board is a little restrictive to artwork, so I've come up with a guide to show how print looks on screen vs a printed sample. I've designed these cards which show how colours/images look printed. Go to www.acdsleeve.com/brown and you can view a PDF which has the closest representation I could manage to get artwork on screen vs. print on brown. If you'd like one of these cards sending out send me your address and I'll get one in the post ready for when I take on orders.

From those base products pretty much everything is customisable, every design can now have cut out elements of artwork. If there's something I don't offer just let me know what you're after and I'll see if I can help, in the years since ACDSleeve ended I've worked on all sorts of packaging design so I'm much more adept at packaging all sorts. It doesn't just need to be music anymore. There's nowhere else with a set up like this, with structural design, print and manufacture all under one roof.

All formats will be catered for. Printed 12" packaging initially will need a bit of thought as it's right at the limit of the size easily printable on short runs, but there will be work arounds on this. Unprinted 12" sleeves with "die cut" custom artwork are doable but need a little more development. Inserts/bellybands/sleeves are all doable as they won't be cut/creased by hand anymore, which always made them far too expensive to offer.

Creating blanks for DIY or screenprinted projects will be much more straightforward and much more flexible than just the 4 Panel CD case I used to offer. It's something I'll offer down the line, but if you're in need of blank packaging just send me an email and I'm sure I'll be able to help.

There is a lot more scope to work on limited versions of existing releases, for example a pre-order or tour version of an album with limited sleeve/additional piece of packaging to go alongside existing mass produced packaging. I think low volume interesting packaging will be a big part of what I do.

There is still a little way to go with development, testing and finalising of the base ideas, and figuring out what all the equipment is capable of. I have gone over all the ideas countless times in my head over the last 12 months but without the kit to test anything. That time was great to think about ideas and get me to a point where I can hit the ground running, but it's also caused the problem that there are so many ideas I want to look into and only one of me here...and now I have the equipment here I keep getting distracted designing new products rather than getting things ready for orders.

Sign up to the mailing list on the homepage to be informed of when I’ll be taking on initial orders to test the waters.